Design of Experiments (DOE) is a methodology that can be effective for general problem-solving, as well as for improving or optimizing product design and manufacturing processes. Specific applications of DOE include identifying proper design dimensions and tolerances, achieving robust designs, generating predictive math models that describe physical system behavior, and determining ideal manufacturing settings. This course utilizes hands-on activities to help you learn the criteria for running a…

This course is verified by Probitas Authentication as meeting the AS9104/3A requirements for continuing Professional Development. This four-hour short course will provide an overview of design considerations for electrohydrostatic actuation for transport and business aircraft applications. The instructor will present the critical topics of electrohydrostatic actuation (EHA) from a systems development perspective (V-Approach). Beginning with aircraft system requirements, the instructors will then…

Led by our senior GD&T professionals with a wide variety of industry background and experience, this one-day GD&T Review and Application course is designed for organizations who have participated in training through SAE but are looking for further clarification on how to apply GD&T best practices to specific organizational drawings. Designed to assist your design teams with highly complex design analysis problems and to support your teams through real world drawing examples, the instructor will …

This course covers the five types of FMEAs with emphasis on constructing Design and Process FMEAs. Each column of the FMEA document will be clearly explained using an actual FMEA example. The course covers various methods for identifying failure modes, effects and causes with special attention given to severity, occurrence, and detection tables and how to develop effective recommended actions strategies. Throughout the class, participants will be involved in exercises/actual projects that demons…

This course is verified by Probitas as meeting the AS9104/3A requirements for Continuing Professional Development. This course serves a dual purpose: it delves into fundamental DFMEA principles and their practical applications while also offering guidance on leading DFMEA teams. Participants will be introduced to crucial FMEA concepts, along with the theoretical foundations before exploring how to implement these concepts in their DFMEA endeavors. Often, the FMEA process can become a mere replic…

While the topic of profile is covered in a basic Geometric Dimensioning & Tolerancing (GD&T) course, those discussions often ignore the variations allowed with these symbols that enable them to be used in complex ways. This advanced web course will clarify the proper use of the profile tolerances in GD&T and uncover the nuances of these two symbols. Since the profile of a surface is arguably the most powerful GD&T symbol, its full potential will be explored. It can be used to control size, form,…

FMEA is an essential part of any product design or redesign. An FMEA requires that a dedicated team take a step-by-step, proactive approach to identifying and analyzing all potential failure modes in a product or service. Completing an FMEA can dramatically improve product performance and reduce manufacturing issues at the component, system, and processing level. This interactive FMEA case study gives you an opportunity to work through the process as an engineer develops an FMEA. From receiving …

How do you solve a problem? Do you find yourself using quick and easy solutions or a structured methodology? Too often, organizations tend to seek quick solutions to a problem without adequately addressing its underlying cause. These decisions often result in solutions that don't work or aren't sustainable, often wasting time, effort, and money. To combat these issues and adopt a fresh approach, teams can use the methods and tools of root cause problem solving. By first viewing a problem as an o…

This course is verified by Probitas Authentication as meeting the AS9104/3A requirements for continuing Professional Development. In today's highly competitive and liability minded environment, Design Reviews (DR) are a must for all major mobility industries such as Automotive, DOD, Aerospace, Agriculture, Recreation, Marine and Rail. While Design Reviews are becoming increasingly important in product liability litigation, they also serve as an effective way to transfer organizational best pract…

The 2-day foundational-level Fundamentals of GD&T course teaches the terms, rules, symbols, and concepts of geometric dimensioning and tolerancing, as prescribed in the ASME Y14.5-2009 Standard. The class offers an explanation of geometric tolerances, their symbols, tolerance zones, applicable modifiers, common applications, and limitations. It explains Rules #1 and #2, form and orientation controls, the datum system, tolerance of position (RFS and MMC), runout, and profile controls. Newly acqui…

This course is offered in China only and presented in Mandarin Chinese. The course materials are bilingual (English and Chinese). Energy conservation and emission reduction has always been a goal for many countries. Especially since the introduction of China VI Vehicle Emission Standards and CAFC & NEV Credit Regulation, the output of NEVs has grown explosively while accompanied by a large number of car fire burning problems and complaints about the shortening of proclaimed electric-only driving…

This course is offered in China only and presented in Mandarin Chinese. The course materials are bilingual (English and Chinese). As the complexity of products increases, traditional text-based systems engineering can no longer meet the needs. To solve the problem, Model-based Systems Engineering offers a unified communication platform among relevant staff by carrying out diagram-based unambiguous description, analysis and design for the demand, and structure and behavior of complex systems in t…

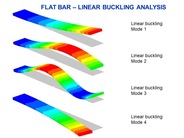

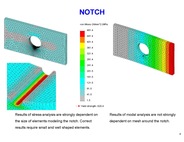

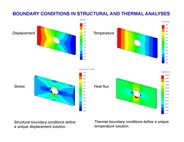

Finite Element Analysis (FEA) has been an indispensable tool for design simulation for several decades but this wide spread use has been limited to simple types of analyses. Relatively recently, more advanced analyses have given easy-to-use interfaces enabling design engineers to simulate problems formerly reserved for analysts. FEA Beyond Basics targets the FEA users who wish to explore those advanced analysis capabilities. It will demonstrate how to move past the ubiquitous linear structural a…

This interactive eLearning GD&T training course now utilizes HTML5 for better browser and device compatibility. It contains 23 robust, self-paced learning modules that explain the terms, symbols, modifiers, rules, and basic concepts of geometric tolerancing as prescribed in the ASME Y14.5-2018 Standard. Progress is easily measured with instant feedback throughout each lesson that reinforces and aids in concept retention, allowing the learner to determine where further review may be needed. Full …

Hybrid Electric Vehicle (HEV) models currently populating the vehicle electrification landscape indicate their dominance in the market. Although electric, plug-in, and fuel cell vehicles are making inroads in the market, the HEV stands as the market leader in adoption, and manufacturers have no plans on diminishing HEV production. HEV powertrain operation is totally different from the traditional vehicle. It is essential to understand the various operating modes and how failure modes in the hybr…

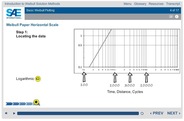

Weibull Analysis is the starting point for solving most issues related to product reliability, maintainability, supportability, quality, safety, test planning, and cost control. Weibull Analysis is popular worldwide as the best method for modeling and predicting variability and failure of designs, products, and systems. Instructor Wes Fulton will provide a solid overview of Weibull Solution Methods including an explanation of 16 additional Weibull Analysis capabilities, or Weibull Extensions. Th…

Design of Experiments is a statistically based, structured approach to product or process improvement that will quickly yield significant increases in product quality and subsequent decreases in cost. Products and processes can be designed to function with less variation and with less sensitivity to environmental factors or customer usage. While still maintaining high quality from a customer's viewpoint, products and processes can utilize lower cost materials and methods. Specifications can be o…

This four-hour short course provides an overview of hydraulic system design of typical business and commercial aircraft. Topics will include the principles, system architectures, power sources, and the main components and technologies of hydraulic systems including hydraulic power generation, filtration, fluid storage, distribution, sensing and control. The step by step process of designing a hydraulic system will also be reviewed. Additionally, future trends in hydraulic systems will be discuss…

This course is offered in China only and presented in Mandarin Chinese. The course materials are bilingual (English and Chinese). The course directly addresses improved aircraft system design tools and processes, which, when implemented will significantly contribute to simpler, lower cost and even safer airplanes that meet customer quality demands. Adding value to the high-leveraged area of design (reducing design by involving manufacturing) — which is what this course does — can start to revers…

This full-day course is designed to equip engineering professionals with the knowledge and tools needed to combine the strengths of Design Engineering and Systems Engineering into Systems Design Engineering (SDE) principles. These principles will improve engineering efficiency and practically design more sustainable system-level products, all while strategically aligning with digital transformation objectives. Learners will explore the use of System-Level Assessment (SLA) and System Design Asses…

Using tolerance stacks ensures that parts fit together properly, reducing scrap and rework, thereby increasing value. This 3-day advanced-level course includes everything covered in the 2-day foundational-level course. It explains how to use tolerance stacks to analyze product designs and how to use geometric tolerances in stacks. You’ll learn the essential methods used for creating 1D part and assembly tolerance stacks, including these six critical concepts: 1.The importance of stacks 2.The two…

RMS (Reliability-Maintainability-Safety-Supportability) engineering is emerging as the newest discipline in product development due to new credible, accurate, quantitative methods. Weibull Analysis is foremost among these new tools. New and advanced Weibull techniques are a significant improvement over the original Weibull approach. This workshop, originally developed by Dr. Bob Abernethy, presents special methods developed for these data problems, such as Weibayes, with actual case studies in a…

Geometric dimensioning and tolerancing (GD&T) is used as a symbolic way of showing specific tolerances on drawings. GD&T is a valuable tool that effectively communicates the design intent to manufacturing and inspection. It is governed by the technical standard ASME Y14.5-2018 (recently revised from the 2009 edition). This course introduces participants to the GD&T system, providing a working knowledge of the correct interpretation and application of each symbol, general rules, the datum system,…

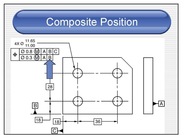

While the basics of position are covered in a standard Geometric Dimensioning & Tolerancing (GD&T) course, and sometimes a lone example of composite position is given, those discussions often overlook the variations allowed that enable more accurate control based on part function. This advanced web course will clarify the proper use of “double-decker” position controls in GD&T. There are two distinct types: composite position (one symbol) and two single-segment position controls (two symbols). T…

Many companies are starting to recognize the benefits additive manufacturing (AM) offers in terms of speed, simplicity, reliability, and cost. Additive manufacturing is a process in which a three-dimensional computer model design s built into a physical object by joining thin layers of material. AM is a versatile field that encompasses a variety of methods, materials, and applications. The one-hour courses in this bundle explain the fundamental concepts of additive manufacturing, including the m…

This 1-day introductory-level course builds on fundamentals of geometric dimensioning and tolerancing and teaches the impact of GD&T on the manufacturing process. The course focuses on the basic requirements of engineering drawings, size dimensions, form tolerances, and the datum system, as well as how tolerancing requirements affect production. Each participant receives: A GD&T for Manufacturing Workbook, A GD&T Ultimate Pocket Guide (2009), and Class handouts. Newly acquired learning is rein…

Electric and hybrid vehicle engineers and designers are faced with the important issue of how to adequately configure required powertrain system components to achieve needed performance, occupant accommodation, and operational objectives. This course enables participants to fully comprehend vehicle architectural/configurational design requirements to enable efficient structural design, effective packaging of required components, and efficient vehicle performance for shared and autonomous operati…

This 2-day foundational-level course builds on geometric dimensioning and tolerancing fundamentals and teaches an introduction of how to inspect GD&T requirements. The course offers an explanation of the geometric symbols, rules, and concepts, the datum system, and how to inspect GD&T requirements using tools from the four categories of inspection tools (CMM; comparison instruments and fixed gages; hand tools and open set up; and production gaging systems). Each participant receives: A Fundamen…

This 2-day foundational-level course teaches advanced geometric dimensioning and tolerancing topics as prescribed in the ASME Y14.5M-1994 Standard. The class offers an in-depth explanation of advanced GD&T topics including: Product design and functional dimensioning Feature and feature of size Dimensioning standards on drawings Rigid and flexible (non-rigid) parts Requirements for parts measured in the restrained state Datum usage on restrained (non-rigid) parts Calculating advanced application…

This 1-day introductory-level course offers an explanation of features in the ASME Y14.5-2009 Standard and compares them to the 1994 Standard. The course covers the pertinent changes made to the Y14.5 standard, including how the subject matter has been reorganized and about new sections that have been created for profile, orientation, and form. Each participant receives: An ASME Y14.5 1994-2009 Comparison Workbook, Class handouts, A GD&T Ultimate Pocket Guide (2009), and An ASME Y14.5 1994-2009 …

Fastener experts believe that upwards of 95% of all fastener failures are the result of either the wrong fastener for the job or improper installation. Improper installation or incorrect fastener selection can result in catastrophic loss or damage. Learn how to avoid issues by getting the answers in this course. Our extremely knowledgeable instructor will guide participants through the basics of fastener engineering, design considerations for specific applications, tightening strategies, tension…

Fatigue is a structural failure mode that must be recognized and understood to develop products that meet life cycle durability requirements. In the age of lightweighting, fatigue strength is an important vehicle design requirement as engineers struggle to meet stringent weight constraints without adversely impacting durability. This technical concept course introduces the fatigue failure mode and analysis methods. It explains the physics of material fatigue, including damage accumulation that m…

During this DFMEA Overview and Application course, participants will be introduced to important FMEA concepts, the basic theory behind the concepts, then discuss how these concepts can be applied to the customer's design FMEA activities. Participant activities include: reading assignments, group discussions, exercises, building Block Diagrams as a group, and beginning a DFMEA on a customer’s product.

Introduction to Power Electronic Converters: In this course, you will learn why we need power converters. We will discuss the basic principles of power conversion and you will receive a brief overview of the various types of power converters. You will learn how to recognize different voltage, current, and power levels, as well as the AC or DC character of electrical power, through examples of common, present-day electrical applications. Power conversion and efficiency in battery systems: In this…

This course will explain all phases of the DRBFM methodology and provide details on how to accomplish the specific steps. With the Design Review Based on Failure Modes (DRBFM) and Design Review Based on Test Results (DRBTR) Process Guidebook that is bundled with the course, the instructor will provide specific information on each step. Formats, examples, notes and homework slides will be used to illustrate the defined steps of the new SAE J2886 DRBFM Recommended Practice. Similarities in content…

Design for Manufacturing and Assembly (DFM+A), pioneered by Boothroyd and Dewhurst, has been used by many companies around the world to develop creative product designs that use optimal manufacturing and assembly processes. Correctly applied, DFM+A analysis leads to significant reductions in production cost, without compromising product time-to-market goals, functionality, quality, serviceability, or other attributes. This course will include information on how DFM+A fits in with QFD, Concurrent…

This course is verified by Probitas Authentication as meeting the AS9104/3A requirements for continuing Professional Development. Reverse engineering has become a common and acceptable practice utilized by many original equipment manufacturers and suppliers. This course focuses on the application of modern technologies used to decode the design details and manufacturing processes of an existing part in the absence of the original design data. It emphasizes the real-life practice of reverse engin…

This course is offered in China only and presented in Mandarin Chinese. Driving simulator is a key component of automotive interactive design, which can provide objective data to support both the effectiveness of design and user experience. On the other hand, driving simulator and the design of its experiments are major challenges, as improper experiment design will lead to consequences such as failure in identifying designing errors of the interactive design itself. Therefore, this course will …

Using tolerance stacks ensures that parts fit together properly, reducing scrap and rework, thereby increasing value. This 2-day foundational-level course explains how to use tolerance stacks to analyze product designs and how to use geometric tolerances in stacks. You’ll learn the essential methods used for creating 1D part and assembly tolerance stacks, including these six critical concepts: 1.The importance of stacks 2.The two-column stack method using the SAE stack spreadsheet 3.Determining …

The 2-day foundational-level Fundamentals of GD&T course teaches the terms, rules, symbols, and concepts of geometric dimensioning and tolerancing, as prescribed in the ASME Y14.5-2018 Standard. The class offers an explanation of geometric tolerances, including their symbols, tolerance zones, applicable modifiers, common applications, and limitations. It explains Rules #1 and #2, the datum system, form and orientation controls, tolerance of position (RFS and MMC), runout, and profile controls. N…

The 2-day foundational-level Fundamentals of GD&T course teaches the terms, rules, symbols, and concepts of geometric dimensioning and tolerancing as prescribed in the ASME Y14.5M-1994 Standard. The class offers an explanation of geometric symbols, including each symbol’s requirements, tolerance zones, and limitations. It compares GD&T to coordinate tolerancing, Rules #1 and #2; form and orientation controls; tolerance of position; runout and profile controls. Newly acquired learning is reinforc…

This course teaches the thought processes involved in assigning GD&T to components, and it changes the way many engineers think about part tolerancing. The course focuses on what constitutes good and poor drawing practices, common dimensioning methods used in industry, using GD&T to communicate system functions on component dimensions, and the logic of how to apply GD&T to components. You’ll also learn how to select datum features and how to fully define component surfaces using GD&T. Establishi…

This two-day foundational-level course teaches Advanced Concepts of GD&T as prescribed in the ASME Y14.5-2009 Standard. It offers an explanation of complex GD&T topics, such as the expanded use of composite position and profile tolerances, customized datum reference frames, the translation modifier, and applying GD&T to non-rigid parts. You’ll learn about functional dimensioning, form controls, the datum system, additional and complex datum feature types, expanded datum target concepts and usage…

This course is offered in China only and presented in Mandarin Chinese. Static perceptual quality is the term applied to the customer’s first impression of a car at the beginning of the buying process including how it looks, feels, and smells. This “first feeling” largely determines whether the customer continues through the purchase process. At present, OEMs have no systematic method for static perceptual quality in the whole vehicle design and development process, especially for the static per…

This training class describes how to develop and safeguard safety critical embedded software in serial projects with Simulink in compliance with ISO 26262 (part 6). Beginning with a general overview of the ISO standard, we proceed by focusing on the ISO 26262 requirements that are specifically relevant to model based development. We address the impact the standard has had on model-based development with Simulink, as well as the requirements for model and software architecture in safety critical …

This course applies advanced theory, physical tests and CAE to the assessment of ride, braking, steering and handling performance, governing state-space equations with transfer functions for primary ride and develop and analyze open loop handling. Building on the analysis of the state space equations, common physical tests and their corresponding CAE solutions for steady state and transient vehicle events. The "state-of-the-art" vehicle dynamics CAE, and common lab and vehicle tests with metrics…

This course is verified by Probitas as meeting the AS9104/3A requirements for Continuing Professional Development. Problems arise in all facets of life. This is particularly true in the business world. Problems impact all aspects of an organization’s operations such as; product development, product quality, process efficiency, marketing efforts, human relations, leadership efforts, financial execution and ultimate profitability. If these problems are not addressed, they inhibit the operation of …

This course introduces basic tire mechanics, including tire construction components based on application type, required sidewall stamping in accordance with DoT/ECE regulations, tread patterns, regulatory and research testing on quality, tire inspections and basic tire failure identification. The course will provide you with information that you can use immediately on-the-job and apply to your own vehicle. This course is practical in nature and supplemented with samples and hands-on activities. …

How do you determine the root cause of a problem or identify which variable settings will make the product or process more "robust"? What if you need to gain a better understanding of a complicated system? Can you identify which variables most affect performance and obtain a well-correlated regression equation that explains how those selected system variables and their interactions affect performance? Design of Experiments (DOE) is an excellent, statistically based tool used to address and solve…

Additive manufacturing (AM), is a manufacturing process of choice for functional part production, adding to the suite of choices a designer has available when designing a part for manufacturing. Like other traditional processes like casting and machining, AM has its set of constraints. An added layer of complexity comes from the fact that there are several different AM processes, and some of the design constraints are process-specific. On the other hand, AM offers a range of opportunities in des…

This six-session course introduces vibration analysis performed with Finite Element Analysis (FEA). By considering time-dependent loads and inertial and damping effects, vibration analysis allows for a more in-depth product simulation thus reducing product development cost and time. The course reviews basic concepts of vibration analysis and illustrates how they are implemented in FEA to simulate product behavior. The most common types of vibration analysis such as modal, time response, and freq…

This four-hour short course intends to present an overview of electrically powered flight control actuation systems, covering commercial applications. The scope covers issues related to the mechanical design of actuators themselves, with limited reference to their control electronics. Additionally, this course will provide participants an understanding of the design considerations behind these actuation systems.

This course is offered in China only and presented in Mandarin Chinese. HMI design is an Interdisciplinary, which is based on human cognitive psychology and combines humanities, sociology, aesthetics, information science and other disciplines. While automotive technologies can be applied regardless of regions, HMI must be localized, as it is closely related to regional culture, people's living habits and characteristics. At the same time, HMI design has its own complete theoretical system, resea…

This 3-day Fundamentals of GD&T course provides an in-depth study of the terms, rules, symbols, and concepts of geometric dimensioning and tolerancing, as prescribed in the ASME Y14.5-2009 Standard. The course can be conducted in three 8-hour sessions or with flexible scheduling including five mornings or five afternoons. This class includes all the topics from the Fundamentals of GD&T 2-day foundational-level class: an explanation of geometric tolerances, including their symbols, tolerance zon…

This 3-day advanced-level course teaches the advanced concepts of GD&T as prescribed in the ASME Y14.5M-1994 Standard. It can be conducted with flexible scheduling, including 5 mornings or 5 afternoons. The course includes all the topics from the Advanced Concepts of GD&T 2-day foundational-level class: Product design and functional dimensioning, Feature and feature of size Dimensioning standards on drawings Rigid and flexible (non-rigid) parts Requirements for parts measured in the restraine…

The importance of weight reduction in vehicle design is well known. In recent years, OEMs have been working on vehicle lightweight research and application, particularly for new energy vehicles. Currently, many Chinese OEMs establish a lightweight target and expect that weight savings will be distributed among the vehicle’s various systems. This tends to keep the weight reduction effort at the level of parts or partial weight loss design development and application. To be truly effective, vehicl…

Use of Model-Based Systems Engineering (MBSE) has been growing across industry, extending beyond defense and aerospace to include various commercial enterprises such as automotive and healthcare. Tool vendors are quick to point out benefits of this model-based approach and practices but are not always clear how MBSE benefits can be realized on a project. When deployed successfully, several key considerations should be addressed that maximize the value for a use-case. This four-hour class will di…

While the basics of datums are covered in a standard Geometric Dimensioning & Tolerancing (GD&T) course, those discussions often overlook the variations that enable datums to be used in complex ways. This advanced course will detail the proper use of datums, showing their full potential to make your drawings as effective as possible. Most people who use GD&T are familiar with traditional datums derived from flat surfaces, and have adequate knowledge of the principle of establishing 3-2-1 contact…

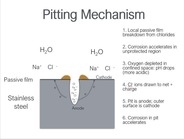

Materials degradation from environmental conditions is a common factor that will often occur in mechanical equipment used in every type of environment. These processes can frequently materialize in unpredicted and harmful ways, especially when they interact and lead to early component damage or failure. Captured from five, two-hour sessions, this course summarizes the mechanisms that cause materials and mechanical components to degrade in service through exposure to deleterious mechanical and en…

This 2-day foundational-level course teaches functional gaging design. It covers how to verify part dimensional requirements using functional gages and other measurement methods. The course offers an explanation of metrology, the roles of the metrologist and inspector, measurement uncertainty, inspection tools, functional gages, inspection planning and reporting, and simulating datums. Each participant receives: A Functional Gaging and Measurement Workbook and Drawing handouts. Newly acquired le…

Design for Manufacturing and Assembly (DFM+A), pioneered by Boothroyd and Dewhurst, has been used by many companies around the world to develop creative product designs that use optimal manufacturing and assembly processes. Correctly applied, DFM+A analysis leads to significant reductions in production cost, without compromising product time-to-market goals, functionality, quality, serviceability, or other attributes. In this two-day course, you will not only learn the Boothroyd Dewhurst Method,…

This course is offered in China only and presented in Mandarin Chinese. Developing environmentally cleaner and more fuel efficient vehicles is transforming the automotive industry worldwide. There are many engineering challenges that must be addressed in designing effective new energy vehicles. The technical knowledge required to understand and make the right decisions with regard to powertrain architecture, powertrain controls, and energy management strategies is critical to success in this mar…

This 3-day advanced-level Fundamentals of GD&T course is an in-depth study of the terms, rules, symbols, and concepts of geometric dimensioning and tolerancing as prescribed in the ASME Y14.5M-1994 Standard. The course can be conducted in three 8-hour sessions or with flexible scheduling including five mornings or five afternoons. This class includes all the content from the Fundamentals of GD&T 2-day foundational course: an explanation of geometric symbols, including each symbol’s requirements…

This 3-day Fundamentals of GD&T course provides an in-depth study of the terms, rules, symbols, and concepts of geometric dimensioning and tolerancing, as prescribed in the ASME Y14.5-2018 Standard. The course can be conducted in three 8-hour sessions or with flexible scheduling including five mornings or five afternoons. This class includes all the topics from the Fundamentals of GD&T 2-day foundational-level class: an explanation of geometric tolerances, including their symbols, tolerance zon…

The Process FMEA and Control Plan program introduces the basic concepts behind this important tool and provides training in how to conduct an effective PFMEA. First, the course explains what a PFMEA is and how it improves the long-term performance of your products, services and related processes by addressing process related failures. The role of the PFMEA in the overall framework of Quality Management System Requirements is explained as well as the role of the PFMEA in the Advanced Product Qual…

Analysis of tolerance stacks varies widely. This web course introduces the basic tools to create a common methodology for tolerance stack-ups, and ensure seamless documentation. Participants will create 1-D tolerance stacks for parts and assemblies that use geometric dimensioning and tolerancing using a tolerance stack spreadsheet. This simple, manual spreadsheet method produces an easily interpreted and checked documentation trail, and is easily adaptable to common electronic spreadsheet progra…

Finite Element Analysis (FEA) is a powerful and well recognized tool used in the analysis of heat transfer problems. However, FEA can only analyze solid bodies and, by necessity thermal analysis with FEA is limited to conductive heat transfer. The other two types of heat transfer: convection and radiation must by approximated by boundary conditions. Modeling all three mechanisms of heat transfer without arbitrary assumption requires a combined use of FEA and Computational Fluid Dynamics (CFD). T…

This course is verified by Probitas Authentication as meeting the AS9104/3A requirements for continuing Professional Development. Engineers and managers involved with product development are constantly challenged to reduce time to market, minimize warranty costs, and increase product quality. With less and less time for testing, the need for effective accelerated test procedures has never been greater. This course covers the benefits, limitations, processes, and applications of several proven ac…

This course is verified by Probitas Authentication as meeting the AS9104/3A requirements for continuing Professional Development. Why is a design for manufacturing, assembly and automation so important? This introductory course on airframe engineering will cover the importance of design for manufacturing, assembly and automation in aerospace. It will review what the key drivers are for a “good” design and some of the key points for manufacturing and assembly of aircraft components. It will look …

This course is verified by Probitas as meeting the AS9104/3A requirements for Continuing Professional Development. In this one-day course on Design Verification Plan and Report Overview and Application, participants will be introduced to important concepts, the basic theory behind the concepts, and discuss how these concepts can be applied to the client's design reliability activities. Participant involvement will be maximized to demonstrate and reinforce the concepts through reading assignments…

This course is verified by Probitas Authentication as meeting the AS9104/3A requirements for continuing Professional Development. In the Aerospace Industry there is a focus on Defect Prevention to ensure that quality goals are met. Failure Mode and Effects Analysis (PFMEA) and Control Plan activities are recognized as being one of the most effective, on the journey to Zero Defects. This two-day course is designed to explain the core tools of Design Failure Mode and Effects Analysis (DFMEA), Proc…

This course is offered in China only and presented in Mandarin Chinese. The course materials are bilingual (English and Chinese). This course is verified by Probitas as meeting the AS9104/3A requirements for Continuing Professional Development. This courser will introduce the latest version (2019) of Failure Mode and Effects Analysis (FMEA) Handbook with a focus on DFMEA and PFMEA building. Each column of the FMEA document will also be explained in detail with FMEA examples. The course also incl…

This interactive eLearning GD&T training course now utilizes HTML5 for better browser and device compatibility. It contains 29 robust, self-paced learning modules that explain the terms, symbols, modifiers, rules, and basic concepts of geometric tolerancing as prescribed in the ASME Y14.5-2009 Standard. Progress is easily measured with instant feedback throughout each lesson that reinforces and aids in concept retention, allowing the learner to determine where further review may be needed. Full …

This course is verified by Probitas as meeting the AS9104/3A requirements for Continuing Professional Development. This eLearning course teaches the requirements of AS13100, including the standard's harmonization of aerospace engine manufacturer requirements. Participants explore the flow to the engine manufacturers systems by regulators, customers, and industry. Suppliers learn how to improve overall product quality, compliance, and business performance. Course modules explore each section of t…

Finite Element Analysis (FEA) is a computer-aided engineering (CAE) tool used to analyze how a design reacts under real-world conditions. Useful in structural, vibration, and thermal analysis, FEA has been widely implemented by automotive companies. It's used by design engineers as a design tool during the product development process because it allows them to analyze their own designs while they are still in the form of easily modifiable CAD models, providing quick turnaround times and ensuring …